Sulphuric Acid Concentration Plant

Commercial sulfuric acid is a cheap commodity and in its dilute and impure form does not have good market potential.

Disposal by neutralization with lime is associated with, problems of solid (calcium sulfate) handling and also adds to the cost.

To overcome these problems GOEL offers know-how, and design engineering services for sulfuric acid concentration systems in which the dilute sulfuric acid generated is reconcentrated to the desired level for reuse. That is to say a twofold benefit of eliminating the disposal problem and minimizing fresh commercial acid requirement.

Process Description of Sulphuric Acid Concentration:

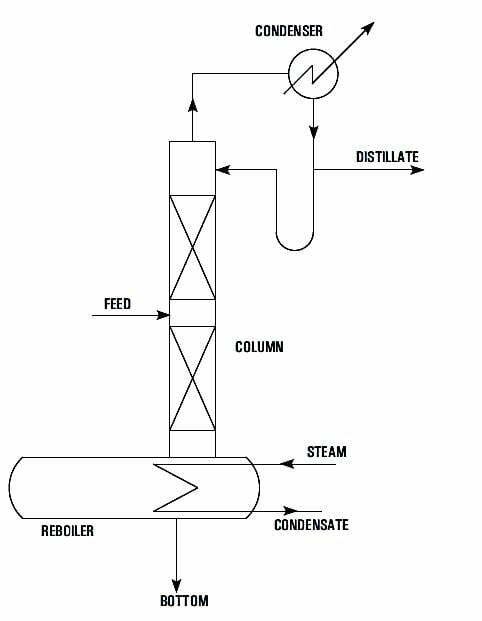

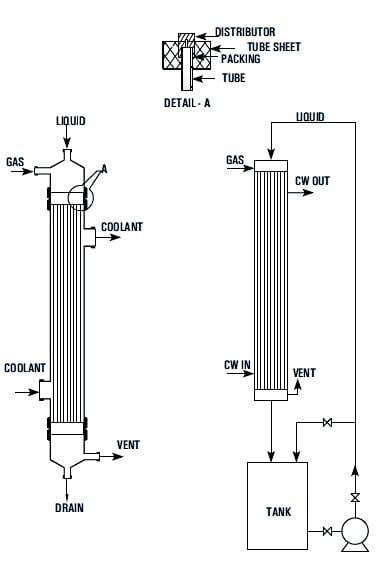

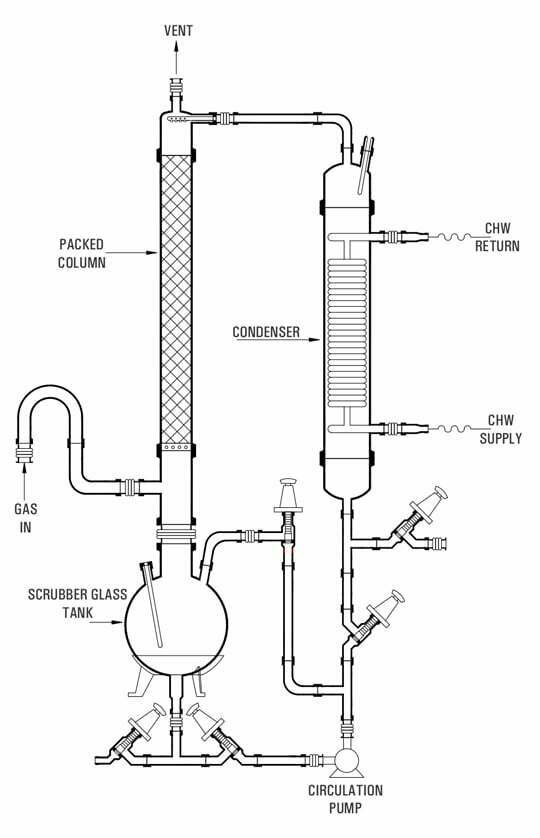

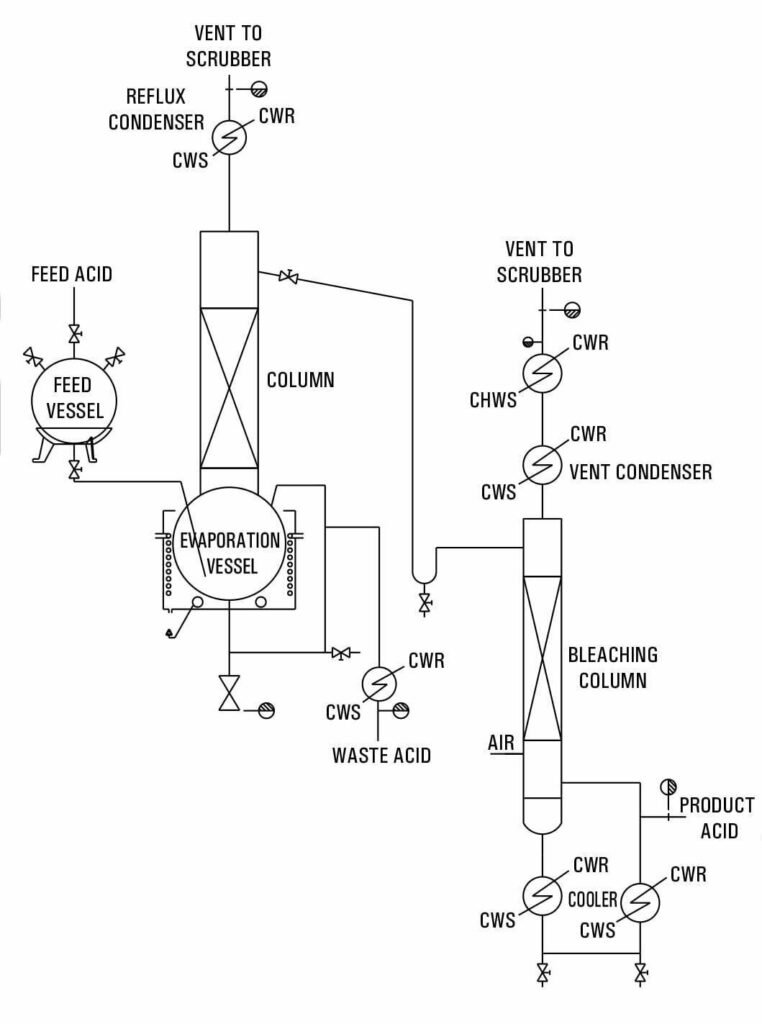

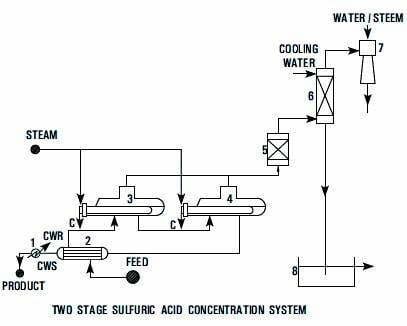

The process is extremely simple & involves the concentration of dilute sulfuric added by evaporation using steam/thermic fluid as heating media under a vacuum. The dilute feed is preheated & fed to a series of evaporators in stages to achieve the concentration level. The vapors from the evaporators are condensed and drained out through barometric legs and non-condensable are removed by an ejector. The final product is cooled and drawn in the storage tank.

REQUIREMENT OF UTILITIES FOR SULPHURIC ACID CONCENTRATION:

The requirement of utilities viz. steam/thermic fluid, cooling water and power vary widely depending on feed rate, feed concentration and product concentration. For example for a plant having 50TPD feed containing 50% H2S04 the consumption of utilities for achieving 70% concentration are given below.

| KEY | ||

| 1 | – | PRODUCT COOLER |

| 2 | – | FEED PREHEATER |

| 3 | – | 1ST, STAGE EVAPORATOR |

| 4 | – | 2ND, STAGE EVAPORATOR |

| 5 | – | MIST ELIMINATOR |

| 6 | – | DIRECT COOLER |

| 7 | – | EJECTION |

| 8 | – | SEAL POT |

| C | – | STEAM CONDENSATE |

| CWS | – | COOLING WATER SUPPLY |

| CWR | – | COOLING WATER RETURN |

| 1 | Steam@ 6 bar{g) pressure | : 800 Kg/hr |

| 2 | Cooling water @ 30 °C | : 70 Cu M/hr |

| 3 | Power | : 15 KW |